|

似乎Alfista都愛的新一代Alfa戰略車~僅呈部分技術資料規格分享~

首部搭載1750TBi 235 HP 愛快茱麗葉~

1.6的稅金/235馬力/安全極速242kn/h

Alfa Romeo

NEW MODEL 'Giulietta'

Main technical specifications |

|

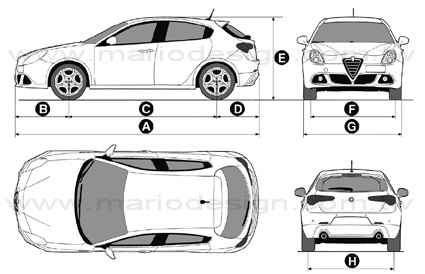

The new Alfa Romeo model shown in Fig. 1 is being launched with the name 'Giulietta'.

The new model comes in a very compact 5-door version and will initially be available with five different engine types, all EURO 5:

Petrol:

| - |

1.4 Turbo petrol 120 HP; |

| - |

1.4 Turbo MultiAir 170 HP; |

| - |

1750 Turbo petrol 235 HP. |

Diesel:

| - |

1.6 JTDM-2 105 HP; |

| - |

2.0 JTDM-2 170 HP. |

Also:

| - |

all Diesel engines come with a particulate filter fitted on the engine to ensure low emissions of harmful exhaust gases; |

| - |

all petrol and diesel engines have a 6-speed gearbox. |

| - |

all engines come with the Start&Stop system as standard outfit, 1750 Turbo petrol excluded. |

The new model is available in different versions: Progression, Distinctive and Sport.

The excellent engine performance is enhanced by tried and tested mechanics with improvements in comfort and handling achieved through technical innovations such as, for example, the multilink rear suspension.

The new Giulietta also provides a high technical level in terms of entertainment as a result of collaboration with the best partners in each sector, such as the Bose Hi-Fi radio with CD player and MP3 with controls on the steering wheel and the 'Blue&Me'® system.

Fig. 1 - Alfa Giulietta

The following pages contain the identification data, dimensions and main technical specifications for the different engine types and a short description of the main innovative/important features of the new model.

Identification data

Engine codes and bodywork versions

| VERSION |

ENGINE |

BODYWORK |

| 1.4 Turbo Petrol |

198A4000 |

940FXA1A 00 |

| 1.4 Turbo MultiAir |

940A2000 |

940FXB1A 01 |

| 1750 Turbo Petrol |

940A1000 |

940FXC1A 02 |

| 1.6 JTDM-2 |

940A3000 |

940FXD1A 03 |

| 2.0 JTDM-2 |

940A4000 |

940FXE1A 04 |

Dimensions

Fig. 2 - Vehicle dimensions in mm (unladen and with standard tyres)

| A |

B |

C |

D |

E |

F |

G |

H |

| 4351 |

955 |

2634 |

762 |

1465 * |

1554 |

1798 |

1554 |

(*) Height is measured with the vehicle unladen.

Small variations in size are possible depending on the dimensions of the rims.

Engines

The new Giulietta will initially be available with five different engines (1.4 Turbo petrol – 1.4 Turbo MultiAir - 1750 Turbo petrol - 1.6 JTDM-2 – 2.0 JTDM-2) mounted at the front, with the following specifications:

| 1.4 Turbo Petrol |

| Engine marking |

198A4000 |

| Total displacement |

1368 cc |

| EEC max. power |

88 kW – 120 HP |

| At a speed of |

5000 rpm |

| EEC max. torque |

206 Nm – 21 kgm |

| At a speed of |

1750 rpm |

| Timing |

DOHC |

| Fuel feed |

Electronically controlled phased sequential multipoint |

| electronic injection with turbocharger and intercooler |

| Max. speed |

195 km/h |

|

|

| 1.4 Turbo MultiAir |

| Engine marking |

940A2000 |

| Total displacement |

1368 cc |

| EEC max. power |

125 kW (170 HP) |

| At a speed of |

5500 rpm |

| EEC max. torque |

230 Nm (23.4 kgm) (*) - 250 Nm (25.4 kgm) (**) |

| At a speed of |

2250 rpm (*) - 2500 rpm (**) |

| Timing |

SOHC |

| Fuel feed |

Phased sequential electronic injection with detonation |

| control and intake valve variable actuation |

| Max. speed |

218 km/h |

| (*) in Normal mode |

|

| (**) In Dynamic mode |

|

| 1750 Turbo petrol |

| Engine marking |

940A1000 |

| Total displacement |

1742 cm³ |

| EEC max. power |

173 kW – 235 HP |

| At a speed of |

5500 rpm |

| EEC max. torque |

300 Nm (30.5 kgm(*) - 340 Nm (34.6 kgm) (**) |

| At a speed of |

4500 rpm (*) - 1900 rpm (**) |

| Timing |

DOHC |

| Fuel feed |

Electronically controlled phased sequential multipoint |

| electronic injection with turbocharger and intercooler |

| Max. speed |

242 km/h |

| (*) in Normal mode |

|

| (**) In Dynamic mode |

|

| 1.6 JTDM-2 |

| Engine marking |

940A3000 |

| Total displacement |

1598 cm³ |

| EEC max. power |

77 kW –105 HP |

| At a speed of |

4000 rpm |

| EEC max. torque |

280 Nm (28.5 kgm) - 320 Nm (32.6 kgm) (**) |

| At a speed of |

1500 rpm (*) - 1750 rpm (**) |

| Timing |

DOHC |

| Fuel feed |

Direct injection with electronically-controlled Multijet |

| Common Rail system, with turbocharger and intercooler |

| Max. speed |

185 km/h |

| (*) in Normal mode |

|

| (**) In Dynamic mode |

|

| 2.0 JTDM-2 |

| Engine marking |

940A4000 |

| Total displacement |

1956 cm³ |

| EEC max. power |

125 kW - 170 HP |

| At a speed of |

4000 rpm |

| EEC max. torque |

320 Nm (32.6 kgm) (*) - 350 Nm (35.6 kgm) (**) |

| At a speed of |

1500 rpm (*) - 1750 rpm (**) |

| Timing |

DOHC |

| Fuel feed |

Direct injection with electronically-controlled Multijet |

| Common Rail system, with turbocharger and intercooler |

| Max. speed |

218 km/h |

| (*) in Normal mode |

|

| (**) In Dynamic mode |

|

Description of the engines

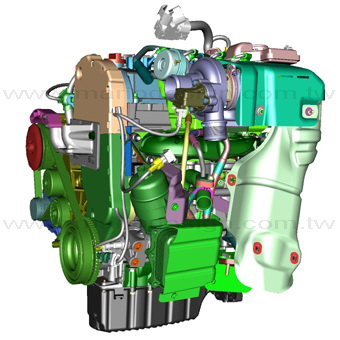

1.4 Turbo petrol (120 HP)

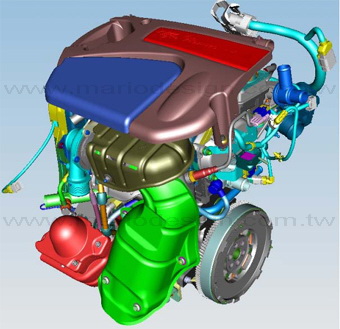

The Giulietta has a supercharged petrol engine known as 'Turbo Petrol', shown in Fig. 3.

Its peculiar features are: performance, responsiveness to acceleration, low consumption, simple construction, sturdiness and reliability.

The engine is 4-cylinder in line, 1368 cc, 120 HP type, with DOHC, 16 valve timing system, supercharged and with engine management having integrated electronic injection/ignition system. The timing control occurs by a toothed belt and hydraulic tappets with cups.

The fixed geometry turbocharger managed by the control unit (Engine Management Node) provides the supercharging by means of a turbocharger pressure solenoid valve regulating the waste gate actuator and a shut-off solenoid valve.

Fig. 3

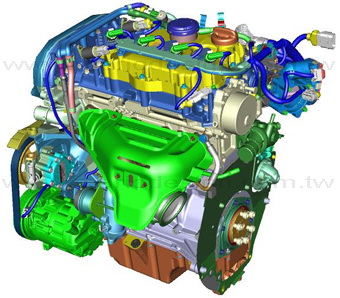

1.4 Turbo MultiAir (170 HP);

The 1.4 Turbo, 170 HP engine shown in Fig. 4 (already used on MiTo), is featured by:

| - |

new fixed geometry turbocharger; |

| - |

new control unit, with modified mapping. |

Fig. 4

MultiAir technology

MultiAir technology (first adopted on the 1.4, 16v 4 cylinder engines for MiTo, 105 HP naturally aspirated and 135 HP/170 HP turbocharged versions) aims at offering remarkable advantages as for consumption and driving pleasure, while keeping lightness and comfort features typical of petrol engines.

MultiAir is a new electrohydraulic management system for intake valves. This system achieves a dynamic and direct control of air flow and combustion through optimised intake valve opening processes, independent for each cylinder.

Therefore, it offers the possibility of managing the most suitable closing time of intake valve optimised the engine volumetric efficiency, to the advantage of the max. torque, especially at low speed.

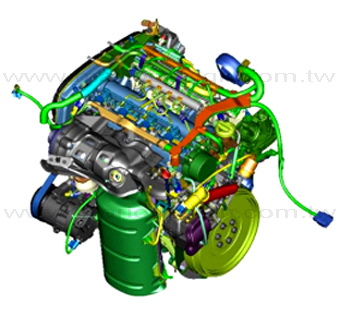

1750 Turbo petrol (235 HP)

The 1750 Turbo petrol, 235 HP engine, shown in Fig. 5, is a supercharged, direct injection engine, with double continuously variable valve timing. The new engine differs from the 200 HP, already used on Alfa 159, due to the use of a special turbocharger with larger vans, for a higher gas/air flow.

The main features of the new 235 HP engine are:

| - |

four cylinder in-line arrangement; |

| - |

dual overhead camshaft with 16-valve timing system; |

| - |

petrol direct injection fuel system; |

| - |

dual continuous phase transformer (intake and exhaust side); |

| - |

cylinder head, oil sump and timing cover in aluminium alloy; |

| - |

cast iron crankcase; |

| - |

cylinder liners are directly fitted in the engine block; |

| - |

hydraulic tappets; |

| - |

water pump inside the head; |

| - |

oil filter built into the engine block; |

| - |

timing with belt control and roller rockers (Roller Finger); |

| - |

electronic accelerator and motorised throttle body; |

| - |

pistons with negative piston bowl (to direct and concentrate the fuel spray to the spark plugs) |

| - |

connecting rods with with fracture-split caps (to ensure correct coupling at assembly) |

| - |

ignition system with 4 coils on top (with coils on top of spark plugs) |

| - |

two oxygen sensors; |

| - |

use of a new generation turbocharger coupled to an innovative Pulse Converter exhaust manifold (which optimises exhaust pressure pulses to increase torque at low engine speed; in practice, it increases exhaust gas speed between valves and turbine). |

| - |

Both the manifold and the turbine are made of microcast steel to withstand very high operating temperatures and therefore reduce consumption on motorways at medium-to-high speed. |

Fig. 5

1.6 JTDM-2

Giulietta has a supercharged 1.6 JTDM-2 16v diesel engine, shown in Fig. 6, from the JTDM-2 ('second generation' MultiJet) family, with a max. power of 105 HP at 4000 rpm and max. torque of 280 Nm at 1500 rpm (320 Nm at 1750 rpm in Dynamic mode).

This fixed geometry turbocharger engine features performance, responsiveness in acceleration, low consumption, simple construction, sturdiness and reliability.

Fig. 6

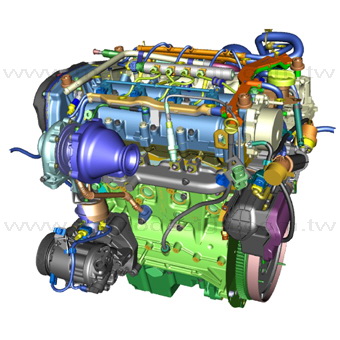

2.0 JTDM-2 engine

Also the 2.0 JTDM-2 16v engine, shown in Fig. 7, from the JTDM-2 ('second generation' MultiJet) family, has a max. power of 170 HP at 4000 rpm and max. torque of 320 Nm at 1500 rpm (350 Nm at 1750 rpm in Dynamic mode).

The 2.0 JTDM-2 16v engine is the natural evolution of the well-known 1.9 JTDM from the point of view of performance (increased torque and power) and level of emission.

The main differences are:

| - |

increased displacement by increasing bore from 82 mm to 83 mm; |

| - |

compression ratio decreased from 17.5:1 to 16.5:1 to obtain a considerable decrease in NOx emissions. |

| - |

new engine configuration with new 'low voltage' spark plugs allowing for shorter pre-heating times. |

| - |

respect of Euro 5 emission values guaranteed by using a close-coupled type DPF and an advanced exhaust gas recirculation (EGR) system in which all subcomponents are grouped into a single, compact element (EGR module). |

| - |

the increase in performance (due to the increase in the displacement and the use of a new variable geometry turbocharger) is combined with a reduction in consumption. |

Fig. 7

Alfa dna system (car dynamic control system)

(for versions/markets where provided)

The Giulietta uses the Alfa dna system: an innovative device which, working on the vehicle dynamic control systems, adjusts the car setup to meet the customer''s requirements, intervening on the on board electronics.

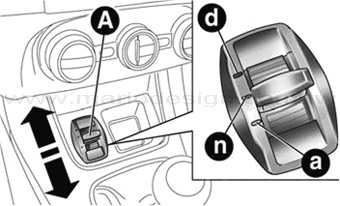

The Alfa dna system has three operating modes (d, n, a) which the customer can select using the lever (A - Fig. 8):

d = Dynamic: sports driving mode.

n = Normal: driving mode for normal conditions.

a = All Weather: driving mode for poor grip conditions (such as rain, snow, etc.).

Fig. 8

The components of the car dynamic control involved by the dna system are mainly:

| - |

Engine Control Unit; |

| - |

Instrument Panel; |

| - |

VDC system; |

| - |

Steering. |

Lever

The lever A shown in Fig. 8 is monostable and always remains in the central position.

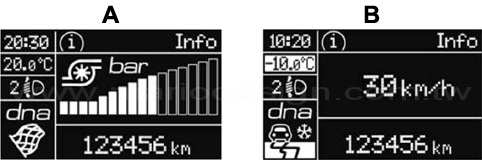

The selected driving mode is indicated by the corresponding LED coming on in the panel (a, n, d in Fig. 8) and by an indication on the reconfigurable multifunction display, as illustrated in Fig. 9.

Fig. 9

A – 'Dynamic' Mode

B – 'All Weather' Mode

'Normal' Mode

In the Normal VDC and ASR mode, the Steering Tuning, DST and Engine are set in normal operation conditions and standard/normal driving mode

Switching the 'Dynamic' mode on/off

To turn the Dynamic mode (Fig. 10) on, move the lever upwards (to d) (see Fig. 8) and keep it in this position for 0.5 seconds until the LED lights up or the word Dynamic on is shown in the instrument panel display (see fig. 10), depending on the display type: multifunction (A) or reconfigurable multifunction (B) type.

Fig. 10

In the Dynamic mode, the systems/devices involved:

| - |

VDC and ASR have intervention thresholds that allow more enjoyable, sportier driving whilst guaranteeing stability and drive power while cornering in acceleration. |

| - |

Steering Tuning uses the sports mode function. |

| - |

DST (Braking standard control coordinated with ABS/VDC): |

| - |

makes a standard control on lateral acceleration; |

| - |

compensates oversteering depending on the VDC/ASR intervention thresholds (a slight movement on the steering wheel encourages the driver to carry out the most appropriate manoeuvre). |

| - |

Engine has a higher response speed: more overboost to increase torque level (where provided). |

| - |

Electronic Q2: improves traction and reduces understeer in acceleration while exiting curves. |

| - |

RAB: by pre-positioning of the brake pads (front and rear) following a rapid release of the accelerator pedal to reduce braking times, shorten stopping distances and improve the brake pedal feeling. |

To turn the Dynamic mode off, and go back to Normal, repeat the same movement with the lever with the same time scales but, in this case, the LED that will light up is the one for the Normal position and the instrument panel (in case of reconfigurable multifunction display) shows the wording Normal on as shown in Fig. 11.

Fig. 11

Switching the 'All Weather' mode on/off

To turn the All Weather mode on (Fig. 12), move the lever downwards, next to the - a - (see Fig. 8) and keep it in this position for 0.5 seconds or until the LED lights up or the instrument panel shows the wording All Weather on, as shown in Fig. 12, depending on the multifunction display (A) or the reconfigurable multifunction display (B).

Fig. 12

In the All Weather mode, the systems/devices involved:

| - |

VDC and ASR: intervention thresholds for top safety and car control even in the event of critical road conditions (e.g. in case of rain, snow, etc.). |

| - |

Steering Tuning: uses the sports mode function. |

| - |

DST: (Higher braking control coordinated with ABS/VDC). |

| - |

makes a standard control on lateral acceleration; |

| - |

compensates oversteering depending on the VDC/ASR intervention thresholds (a slight movement on the steering wheel encourages the driver to carry out the most appropriate manoeuvre). |

| - |

Engine: has a standard response. |

To turn the All Weather mode off and return to Normal, the procedure is the same as described for the Dynamic mode with the difference being that in this case the lever should be moved downwards, next to the letter - a.

Start&stop

System description

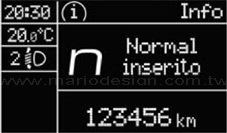

Like MiTo, Giulietta has the new engine stopping/starting system, called Start&Stop (1750 turbo petrol excluded), to reduce consumption, emission of harmful gases (e.g. CO2) and noise pollution.

Remember that:

| - |

with stopped car , the engine stops with gearbox in neutral and released clutch pedal. |

| - |

the engine can only be stopped automatically after a speed of about 10 km/h is reached, to prevent the engine from being repeatedly stopped when driving at walking pace. |

| - |

the engine stopping is signalled by the display of the relevant symbol, shown in Fig. 13, depending on the multifunction display (A) or reconfigurable multifunction (B) type. |

| - |

to restart the engine, just press the clutch pedal. |

Fig. 13

Gear shift indicator

Giulietta uses the 'GSI' (Gear Shift Indicator) to advise the driver to change gear through the necessary indication on the instrument panel (see detail A in Fig. 13).

Shifting when indicated by GSI will help the driver save fuel.

Therefore, for driving oriented towards cutting fuel consumption, it is recommended to stick to 'Normal' or 'All Weather' mode and to follow the suggestions of the Gear Shift Indicator, where the traffic conditions allow it.

When the SHIFT UP (arrow up) icon is shown on the display, the GSI suggests the driver to up-shift, whereas if the SHIFT DOWN icon (arrow down) is displayed, the driver is advised to down-shift.

C635 type gearboxes

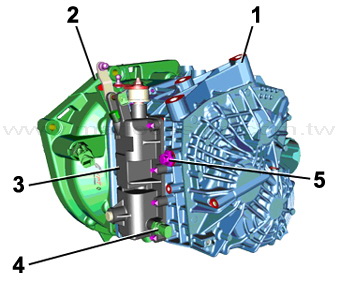

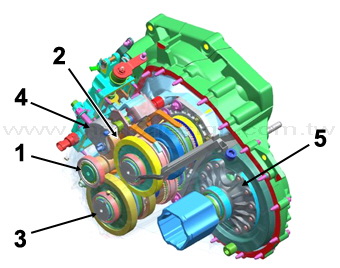

All engines come with a state-of-the art manual gearbox, shown in Fig. 14: the C635 6-speed gearbox.

The C635 gearbox belongs to a new group of transverse, three-axle transmissions designed for improved manoeuvrability, that are more compact than two-axle transmissions.

This type of gearbox is able to withstand and transmit high maximum torque values (up to 350 Nm) and can therefore be fitted on all engines.

The six speeds allow, particularly at motorway speeds, lower engine rpm, with the twofold advantage of less noise in the passenger compartment and a reduction in actual fuel consumption figures.

The clutch release control is hydraulic, built into the gearbox and is operated by the CSC device, with the aim or reducing the operating effort. The splash lubrication system ensures lower wear with higher transmission efficiency and manoeuvrability even at low temperatures.

Fig. 14

Key

1. Gear casing

2. Clutch casing

3. Gear selection/engagement assembly

4. Reversing light switch

5. Reverse gear mounting fixing screw

The main specifications of the new C635 manual gearbox are:

| - |

fixed idler (or cascade gear) manual gearbox with six transmission ratios plus reverse; |

| - |

all synchronised gears (including reverse); |

| - |

free wheel for reverse engagement; |

| - |

toothed wheels with helical teeth; |

| - |

three shafts (see Fig. 15), a main shaft (1) plus two layshafts (2, upper and 3, lower); |

| - |

differential (5) built into gearbox casing; |

| - |

actuation by hydraulically-controlled clutch; |

| - |

casing split into two parts |

Fig. 15

Key

1. Main shaft

2. Upper layshaft

3. Lower layshaft

4. Reverse gear mounting

5. Differential

Transmission ratios

The C635 gearbox, depending on the engines, has the following ratios:

- 1.4 Turbo petrol 120 HP

| 1st |

2nd |

3rd |

4th |

5th |

6th |

Reverse |

Axle |

| 1: 3,900 |

1: 2,118 |

1: 1,484 |

1: 1,116 |

1: 0,897 |

1: 0,767 |

1: 4,000 |

1: 4,118 |

| - 1.4 Turbo MultiAir 170 HP |

| 1st |

2nd |

3rd |

4th |

5th |

6th |

Reverse |

Axle |

| 1: 3,900 |

1: 2,118 |

1: 1,484 |

1: 1,116 |

1: 0,897 |

1: 0,767 |

1: 4,000 |

1: 3,833 |

| - 1750 Turbo petrol 235 HP |

| 1st |

2nd |

3rd |

4th |

5th |

6th |

Reverse |

Axle |

| 1: 3,900 |

1: 2,118 |

1: 1,484 |

1: 1,116 |

1: 0,897 |

1: 0,767 |

1: 4,000 |

1: 3,579 |

| - 1.6 JTDM-2 105 HP |

| 1st |

2nd |

3rd |

4th |

5th |

6th |

Reverse |

Axle |

| 1: 4,154 |

1: 2,118 |

1: 1,361 |

1: 0,978 |

1: 0,756 |

1: 0,622 |

1: 4,000 |

1: 3,421 |

| - 2.0 JTDM-2 170 HP |

| 1st |

2nd |

3rd |

4th |

5th |

6th |

Reverse |

Axle |

| 1: 3,900 |

1: 2,118 |

1: 1,361 |

1: 0,978 |

1: 0,756 |

1: 0,622 |

1: 4,000 |

1: 3,421 |

Braking system

The Giulietta is available (for versions/markets where provided) with the most sophisticated auxiliary electronic and mechanical systems, namely:

VDC system (Vehicle Dynamics Control)

In addition to the ABS there is a VDC (vehicle stability control) system which helps in maintaining directional control if the tyres lose grip; the VDC, in turn, includes the following systems:

| - |

Hill Holder |

| - |

ASR |

| - |

Brake Assist (HBA) |

| - |

MSR |

| - |

CBC |

| - |

ELECTRONIC Q2 (E-Q2) |

| - |

DST |

| - |

RAB |

Hill Holder System (to aid starting uphills).

The Hill Holder system facilitates starting on a hill and is automatically activated in the following cases:

| - |

uphill: vehicle stationary on a road with a gradient higher than 5%, engine running, brake pedal pressed and gearbox in neutral or gear (other than reverse) engaged; |

| - |

downhill: vehicle stationary on a road with a gradient higher than 5%, engine running, brake pedal pressed and reverse gear engaged. |

When setting off the VDC system control unit maintains the braking pressure at the wheels until the engine torque required for departure is reached or for approximately 2 seconds, allowing your right foot to be moved easily from the brake pedal to the accelerator.

ASR (Anti Slip Regulation) system (car traction control function)

It is an integral part of the VDC system. It automatically operates in the event of one or both drive wheels slipping, loss of grip on wet roads (aquaplaning) and acceleration on slippery, snowy or icy roads, etc.

Depending on the slipping conditions, two different control systems are activated:

| - |

if the slipping involves both drive wheels, the ASR intervenes reducing the power transmitted by the engine; |

| - |

if the slipping only involves one of the drive wheels, the ASR intervenes automatically braking the wheel that is slipping. |

Brake Assist (assistance function during emergency braking)

The system, which cannot be turned off, recognises emergency braking (on the basis of the brake pedal operating speed) and speeding up the response of the braking system. The Brake Assist device is deactivated if there is a VDC system failure.

MRS function (engine braking control function when the accelerator is released)

This system is an integral part of the ASR, that intervenes, if there is a sudden downshifting, restoring torque to the engine, thereby preventing excessive drive at the drive wheels which, especially in poor grip conditions, could lead to a loss in stability of the car.

CBC system

This function improves the distribution of the braking pressure at the four wheels (to fully exploit the grip available on the ground) when braking on bends if the ABS intervenes. This control improves stopping distances on bends and, above all, car stability.

Electronic Q2 system (E-Q2)

The Electronic Q2 system takes advantage of the braking system producing behaviour very similar to a limited slip differential.

The front braking system, when accelerating around a curve, acts on the inside wheel to increase the drive to the outside wheel (increased load), dynamically and continuously distributing the torque between the front drive wheels according to driving and road conditions.

The system, combined with MacPherson front suspension, allows particularly effective and sports driving to be achieved.

DST system (Dynamic Steering Torque) (integrating electric steering in the VDC functions)

This function integrates the electric steering into the operation of VDC. For particular manoeuvres, the VDC controls the steering to actuate a steering torque and assist the driver in the best possible way. The system operates the brakes and steering in a coordinated manner to increase the suspension and safety level of the car as a whole.

The steering provides additional torque on the steering wheel.

RAB system

(only with ''Dynamic' mode activated)

It is a function that achieves a pre-positioning of the brake pads (front and rear) following a rapid release of the accelerator pedal to reduce braking times, shortening stopping distances.

System specifications (calipers and discs)

The braking system is the power assisted hydraulic type, comprising two crossover, independent circuits (each circuit acting on one front wheel and the diagonally opposite rear wheel) to ensure braking and stability even if one of the circuits fails.

Based on the performance and weights of the various engine versions, three systems have been defined as described in the table:

| |

1.4 Turbo Petrol |

1.4 Turbo MultiAir |

1750 Turbo Petrol |

| 1.6 JTDM-2 |

2.0 JTDM-2 |

| FRONT BRAKES |

Self-ventilated disc |

Self-ventilated disc |

Self-ventilated disc |

| 281x26 |

305x28 |

330x28 |

Cast iron floating

caliper with 57-mm

piston |

Cast iron floating

caliper with 57-mm

piston |

Aluminium fixed

caliper with 40-mm

pistons |

| REAR BRAKES |

Full disc 264x10 |

Full disc 278x12 |

| Cast iron caliper with 36-mm piston |

Cast iron caliper with 38-mm piston |

| BRAKE BOOSTER |

11' brake servo with 15/16 pump |

Steering control

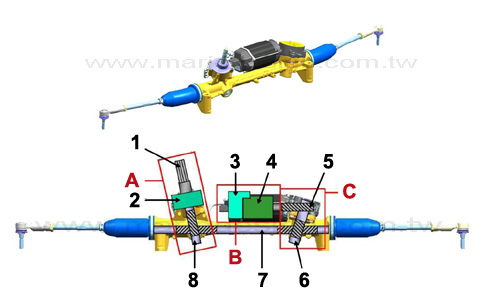

The Giulietta steering control has been designed to guarantee the driver the best possible performance, together with limited effort.

The development of these aims, together with the search for a high level of driving comfort, has led to the creation of a new electric steering on rack (Dual Pinion structure), guaranteeing:

| - |

savings in consumption (up to 3% less than a conventional hydraulic steering system) |

| - |

high performance for managing significant loads at all steering wheel operating speeds (sporty handling) |

| - |

power assisted curves modulated according to driving conditions |

| - |

interaction of steering system with vehicle dynamics (DST) included as part of dna operating strategies |

| - |

reduced turning circle. |

The steering system

The steering column has the following main specifications:

| - |

40-mm telescopic adjustment |

| - |

4° angle adjustment |

| - |

adjustment loads (from 50 Nm to 100 Nm) |

| - |

a 65-mm controlled energy absorption collapse travel in addition to adjustment divided into three stages: initial detachment, collapse travel and end of travel. |

The Dual Pinion system

The Dual Pinion electromechanical steering shown in Fig. 16 is a system made up of two pinions that transmit the axial force necessary to balance the force on the link.

The two pinions are represented by the drive pinion and the power pinion; the drive pinion creates a mechanical link between the steering wheel and the rack, while the power pinion transfers the torque generated by the electric motor to the rack.

As far as the power pinion is concerned, movement is transferred from the crankshaft to a worm screw through a flexible coupling made out of a material similar to that of the drive belts.

Fig. 16

Key

A. Collapsible shaft and power pinion unit

B. Electronic unit

C. Power pinion unit

1. Telescopic shaft engagement point

2. Torque sensor and steering angle sensor

3. NGE (electric steering node)

4. Electric motor

5. Worm screw

6. Power pinion

7. Rack

8. Drive pinion

The shaft is supported in the middle by a system similar to a ball joint that can be used to take up play during the assembly process and at the end by a ball bearing.

The worm screw meshes with a toothed wheel made out of plastic (nylon).

The toothed wheel, in turn, contains a hole housing a toothed metal ring press-fitted to the power pinion to limit the torque reaching the rack due to a pulse effect received by the wheel.

The shaft is supported by two bearings: the first supports radial and axial loads while the second only supports radial loads.

The advantages of the Dual Pinion system over a conventional electrical or mechanical steering system may be shortly classified into the following categories:

| - |

Speed-dependant power assistance |

| - |

Active return |

| - |

DST |

| - |

Compensation for inertia and friction (comfort) |

| - |

Fuel consumption reduction. |

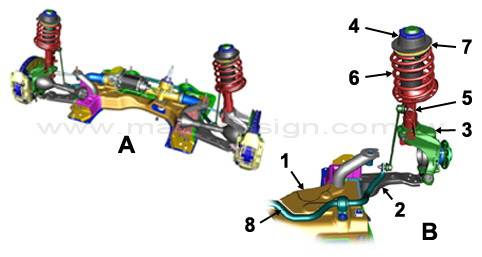

Suspension

The suspension on the Giulietta has been developed with the aim of producing a new reference point for the segment in terms of handling, maintaining a very good level of comfort at the same time.

The MacPherson arrangement for the front suspension, shown in Fig. 17, was a starting point and the new Multi-link layout, shown in Fig. 18, was followed for the rear suspension.

Two type of stiffness were arranged for suspensions: 'Comfort' and 'Sport'; the 'Sport' stiffness is standard fitted on the 1750 Turbo petrol version and, upon demand, for the other versions.

Front suspension

The geometry and elastic features of front suspension (A - Fig. 17), MacPherson type, were studied to reduce as much as possible camber losses, to get high handling performance.

The use of aluminium alloys for the pillars, the use of high strength steels for the wishbones and crossmembers and the optimisation of structural components have made it possible to contain the total weight of the suspension, and the unsuspended masses in particular, with additional benefits in terms of comfort performance.

The considerable stiffness and low weight ensure the structure a high intrinsic frequency, determining optimum vibration performance with the final outcome of ensuring insulation between road and passenger compartment and a following reduction in typical rolling noise.

Fig. 17

The following description concerns front suspension main components, detail B in Fig. 17:

1. Supporting crossmember: it has been designed with high stiffness to improve reaction to side load and therefore handling performance;

2. Wishbones are in two parts, in high resistance steel;

3. Pillar: it comes in aluminium and is 'clamp' type to improve stiffness at side load and therefore handling performance;

4. Dome blocks: designed to optimise the exchanges of forces between suspension and body and dampen vibrations;

5. Shock absorbers: telescopic, with high side stiffness;

6. Springs: they are designed to improve the thrust axis and contain transverse loads on the shock absorber; they further improve comfort and reduce weights thanks to the use of high resistance springs;

7. Flexible rings: they are laid between springs and mounting bases to eliminate possible operating noise;

8. Anti-roll bar: it is 'hollow' type to minimise weight with size selected to reduce rolling motion;

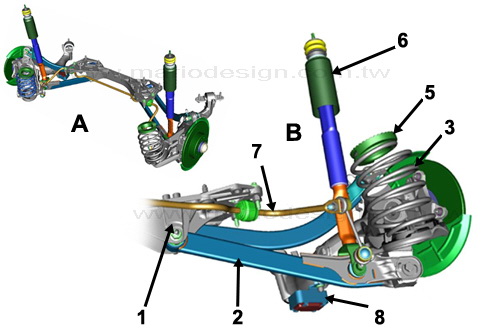

Rear suspension

The rear suspension (A - Fig.18) features a multi-link layout and has been designed to achieve full control of the typical angles to ensure an optimum exchange of forces between road and tyre at all times and therefore guarantee great handling performance.

The suspension structure was partly chosen for its low vertical bulk, which makes it possible to maximise the luggage compartment capacity and thus combine high handling and comfort performance with plenty of passenger room.

On the rear suspension, too, the extensive use of aluminium components made it possible to keep weight down and minimise masses.

Fig. 18

The following description concerns rear suspension main components, detail B in Fig. 18:

1. Mechanical supporting crossmember: it has been designed in aluminium, to improve ratio/stiffness ratio and reaction to side loads, resulting in handling performance improvement;

2. Aluminium wishbones: they feature very low weight and are optimised as for frequencies with the aim of minimising vibration and rolling noise;

3. Springs: the use of high resistance springs achieved a further weight reduction;

4. Bushes: with stiffness settings designed to maximise handling performance and low dynamic stiffening ratios to minimise noise levels transmitted from the road;

5. Flexible rings: they are laid between springs and mounting bases to eliminate possible operating noise;

6. Shock absorbers: they are linked to the lower rod and body, designed for very small dimensions;

7. Anti-roll bar: size selected to increase rear axle rolling stiffness

8. Damping masses.

Wheels

Cold tyre inflation pressure (in bar) - wheel dimensions in inches (')

| Version |

Wheels |

Tyres |

Pressures with medium load |

Pressures with full load |

| Front |

Rear |

Front |

Rear |

|

1.4 Turbo MultiAir

1.6 JTD M-2 |

7Jx16 H2 ET 41 (*) |

195/55 R16 91V REINFORCED (*) |

2.6 |

2.2 |

2.9 |

2.5 |

|

| 7Jx16 H2 ET 41 |

205/55 R16 91V |

2.3 |

2.1 |

2.5 |

2.1 |

| 7.5Jx17 H2 ET 41 |

225/45 R17 91W |

2.3 |

2.1 |

2.6 |

2.2 |

| 7.5Jx18 H2 ET 41 |

225/40 R18 92W REINFORCED (**) |

2.5 |

2.3 |

2.9 |

2.5 |

1.4 Turbo MultiAir

2.0 JTD M-2 |

7Jx16 H2 ET 41 (*) |

195/55 R16 91V REINFORCED (*) |

2.6 |

2.2 |

2.9 |

2.5 |

| 7Jx16 H2 ET 41 |

205/55 R16 91V |

2.3 |

2.1 |

2.6 |

2.2 |

| 7.5Jx17 H2 ET 41 |

225/45 R17 91W |

2.3 |

2.1 |

2.6 |

2.2 |

| 7.5Jx18 H2 ET 41 |

225/40 R18 92W REINFORCED (**) |

2.5 |

2.3 |

2.9 |

2.5 |

| 1750 Turbo Petrol |

7.5Jx17 H2 ET 41 |

225/45 R17 91W |

2.3 |

2.1 |

2.7 |

2.3 |

| 7.5Jx18 H2 ET 41 |

225/40 R18 92W REINFORCED (**) |

2.5 |

2.3 |

3 |

2.6 |

(*) For versions/markets where provided

(**) Tyres not suitable for fitting snow chains.

CONTINUE... if need...

|